When selecting the right model of a desanding plant for trenchless project, it’s important to address key operational parameters and customer concerns to ensure optimal performance. A thorough analysis of the problem, along with understanding the specific operational requirements, will guide the solution.

One customer feedbach that the 500GPM for their new piling rig looks not performance well. They want to know what is the problem and how to address it.

Slurry Overflow: If the issue is related to inadequate processing capacity, causing slurry to overflow from the shaker screen, it suggests that the desanding plant is not handling the required flow rate.

Insufficient Separation Efficiency: If the complaint is regarding minimal differences in mud specific gravity before and after treatment, this indicates that the separation efficiency is not meeting the required standards, likely due to improper shaker screen selection or operational parameters.

Key Operational Parameters to Verify

To resolve these issues, it’s crucial to check the flow rate of the client’s mud pump. The processing capacity of the desanding plant should be carefully matched with the mud pump flow rate. If the system capacity is significantly lower than the pump flow, slurry overflow will occur. This balance ensures that the desanding plant can efficiently process the slurry without underloading or overloading.

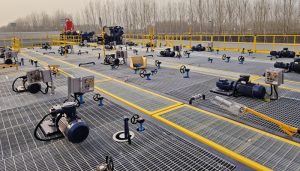

GNMS-500D mud desaning unit Technical Specifications

For example, the GNMS-500D desander plant is designed to handle a maximum processing capacity of 500 GPM. It comes with a double deck screen shale shaker setup, including a 1mm coarse screen and a 0.3mm fine screen under the cyclone, which are crucial for separating coarse and fine solids.

Solution for Improving Separation Performance

If the desanding plant’s capacity is adequate but the goal is to reduce the gravity or solids content of the separated liquid, a finer mesh screen can improve separation efficiency. The following screen options can be considered:

Coarse Screen Options: API 20, API 40, or API 60

Fine Screen Under Cyclone: API 40, API 60, or API 80

It’s important to note the trade-off when choosing finer mesh screens. While finer screens offer better liquid clarity and more effective solids removal, they can reduce processing capacity. The finer the mesh, the slower the processing rate, so the right balance must be struck between liquid clarity and throughput.

In summary, addressing the specific complaint and aligning the desanding plant’s capacity with the pump flow, while carefully selecting the appropriate screen mesh, will optimize performance and ensure the required separation efficiency.