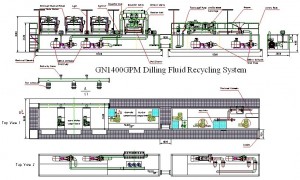

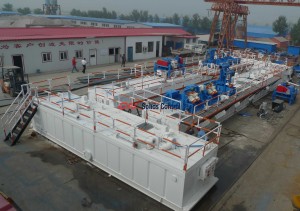

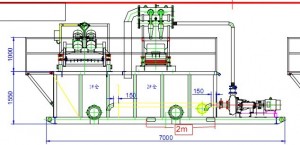

GN Solids Control design and manufacturer drilling mud system specifically for CSG (Coal Seam Gas) Drilling Mud Cleaning System.

The CSG (Coal Seam Gas) exploration and drilling is very popular in Australia.GN Solids Control has exported mud system to Australia for CSG drilling contractors.

About CSG (Coal Seam Gas)

As an end-use product, CSG is the same as natural gas, and can be utilised in all natural gas appliances and commercial applications.The difference between CSG and other natural gas is mostly how it occurs in nature. CSG collects in the coal seam by bonding to the surface of coal particles, whereas other natural gas is stored in the pore spaces between grains of sandstone or similar rock.

Coal seams in the ground are generally filled with water, and it is the pressure of the water that keeps the gas adsorbed as a thin film on the surface of the coal. The cleats, the fracture system of coal, may be interconnected and permeable. In a high quality CSG deposit the cleats are permeable enough to allow gas and water to flow freely through them.

The level of gas produced from a coal bed is dependent on the thickness of the coal, gas content, permeability and the depth of the coal seam.The coal seams that can produce CSG economically are usually between 200m to 1,000m below the surface.

As described by GN Solids Control Clients,in CSG drilling,the drilling mud usually has much fine solids sometimes up to 80% solids.Aslo the CSG drilling is very fast. Continue reading “CSG (Coal Seam Gas) Drilling Mud System”