GN Solids Control is one of the well-known International Brand for drilling Mud Solids Control System & Drilling Waste Management system. GN Solids Control offers the one stop solution for Solids Control treatment of oil gas drilling, CBM drilling, HDD, and water well drilling as well as the construction drilling mud treatment etc.

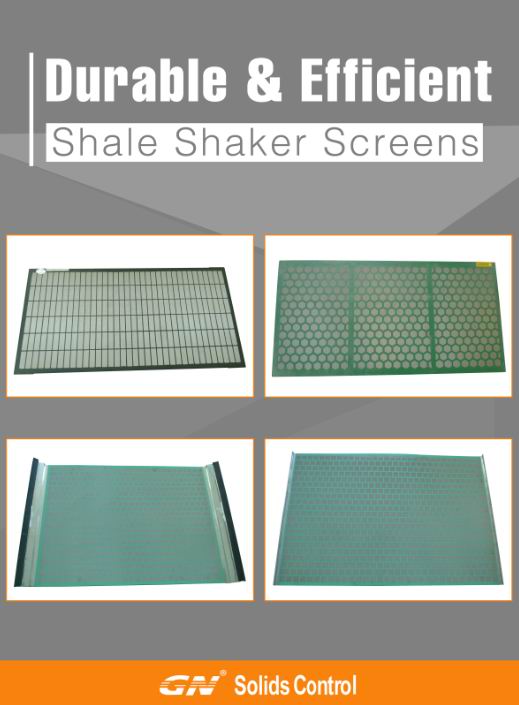

Nearly all drilling mud processing equipment containers shaker screen separation. Replacement shaker screen is a major wearing spare parts for drilling mud system. And it is a big and continue cost. GN Solids Control is specialized in high quality replacement shaker screen for various popular shaker models. GN Solids Control has his own R&D department for shale shaker screens. Clients can also contact GN Solids Control to make customized shaker screen.

Most solids control equipment manufacturer only make some kinds of processing equipment. Like some companies make shale shaker, mud cleaner and agitators, but they are not capacity to make decanter centrifuge or cuttings dryers. Some companies are only capacity to make centrifuges for various industries, they cannot make solids control separation equipment, like shale shaker, mud cleaner, degasser, etc…While some companies are only make pumps, they cannot make separation equipment. And there are some companies only make mud tanks, they are not capacity to make solids control separation equipment by themselves.

GN Solids Control is focusing on full line solids control equipment for various drilling mud. GN Solids Control is specialized in drilling mud liquid and solids separation. All the separation equipment are made by GN Solids Control. In this case, GN Solids Control knows more about the separation equipment, and can offer more reasonable proposal.

Furthermore, electrical control system is another essential point for separation equipment, especially VFD smart control panels for decanter centrifuges. GN Solids Control has his own electrical control department. GN Solids Control electrical engineering business department has comprehensive ability to provide solution for explosion-proof electrical control. GN is able to provide the electric control system, explosion-proof electrical enclosure design and development, fabrication, site installation, program debugging, and other services.

GN Explosion Proof Certification: GN Solids Control electrical control products have been certified by China National standard CNEx, International standard IECEx and European standard ATEX certificate, which enable GN’s products to meet high level market requirements.