A complete package of a wastewater treatment centrifuge unit has been fully manufactured and is now ready for delivery to an oil and gas drilling project in Africa. This system is designed specifically to treat wastewater generated during drilling operations, where effective separation of ultra-fine solids is critical to meeting environmental discharge and reuse requirements. Oil and gas drilling wastewater typically contains fine particles, residual drilling fluids, and chemical additives, which require a high-performance dewatering solution with stable and continuous operation.

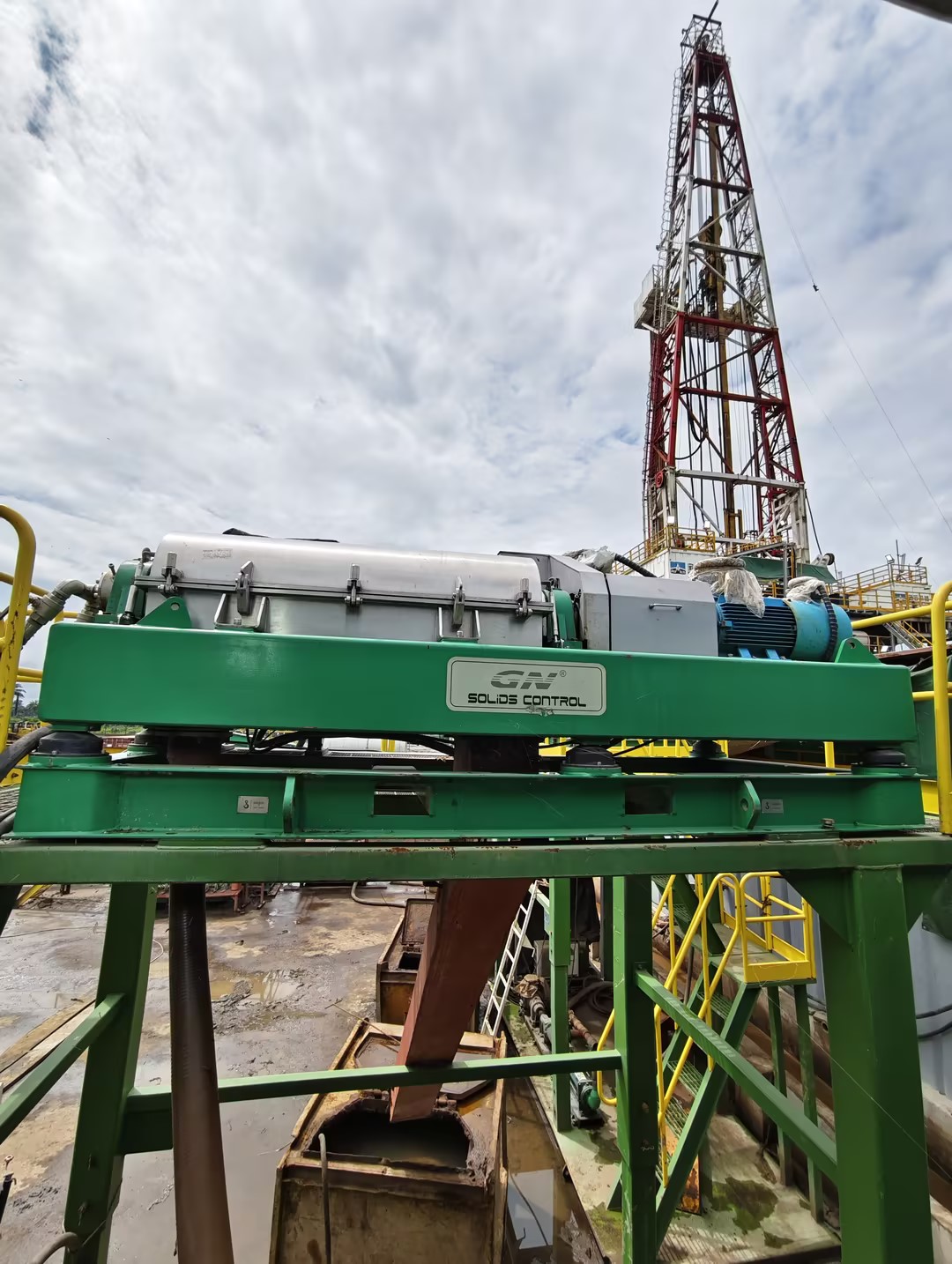

This centrifuge unit represents a high-standard wastewater dewatering system, engineered to handle ultra-fine solids from treated water streams with high separation efficiency. At the core of the system is a high-speed, large-bowl decanter centrifuge. The large bowl diameter and optimized bowl length provide an extended clarification area and higher centrifugal force, allowing the centrifuge to effectively remove very fine solids while maintaining high throughput and low moisture content in the discharged solids.

To ensure smooth and controlled feeding into the decanter centrifuge, the package is equipped with a matched feeding screw pump. The screw pump is specially selected for its ability to handle variable flow rates and abrasive slurry without causing excessive shear, ensuring stable operation and protecting both the pump and the centrifuge from premature wear.

The system also includes a complete chemical dosing unit, which allows precise injection of flocculants or other treatment chemicals into the wastewater stream. Proper chemical dosing enhances particle agglomeration, significantly improving the separation efficiency of ultra-fine solids and reducing the load on the centrifuge.

In addition, a clean water tank with a dedicated transfer pump is integrated into the package. The clarified water separated by the centrifuge can be collected, stored, and transferred for further treatment, reuse, or safe discharge in accordance with local environmental regulations.

All components of the centrifuge unit are mounted on a telescopic skid structure designed to support and secure the entire package. This skid-mounted design ensures ease of transportation, installation, and on-site integration, while providing structural stability during operation. The complete system reflects a reliable and efficient solution for wastewater treatment in oil and gas drilling fields.

In industrial areas or contaminated sites, the hydrovac slurry may also contain hydrocarbons, chemical residues, or other forms of subsurface contamination. Due to its complex and highly variable composition, this slurry is often classified as industrial or controlled waste. As a result, it cannot be discharged directly into municipal drainage systems, open land, or water bodies. Proper handling, transportation, and treatment are required to ensure compliance with environmental regulations and to minimize impacts on local ecosystems and infrastructure.

In industrial areas or contaminated sites, the hydrovac slurry may also contain hydrocarbons, chemical residues, or other forms of subsurface contamination. Due to its complex and highly variable composition, this slurry is often classified as industrial or controlled waste. As a result, it cannot be discharged directly into municipal drainage systems, open land, or water bodies. Proper handling, transportation, and treatment are required to ensure compliance with environmental regulations and to minimize impacts on local ecosystems and infrastructure.