NEWS

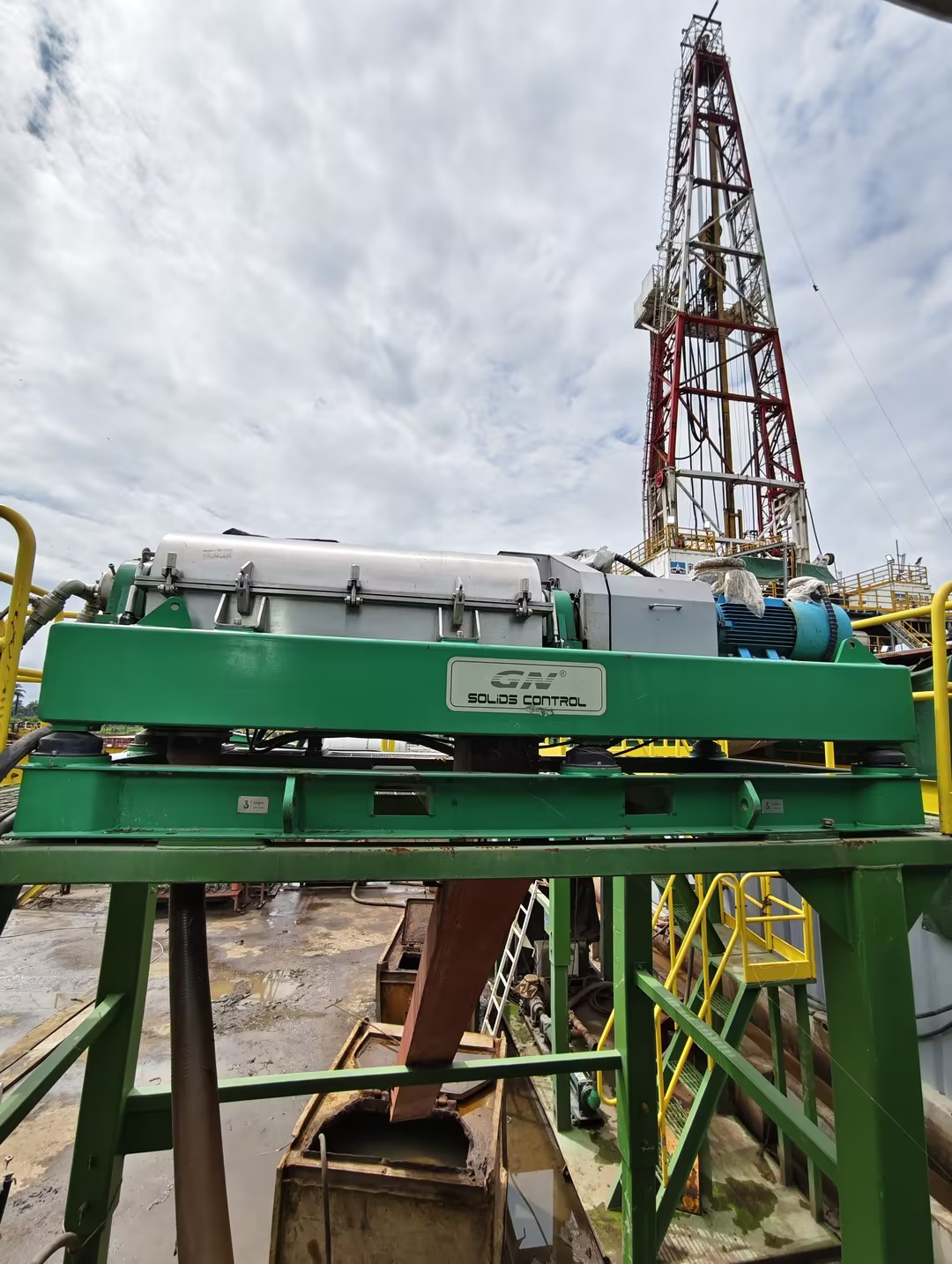

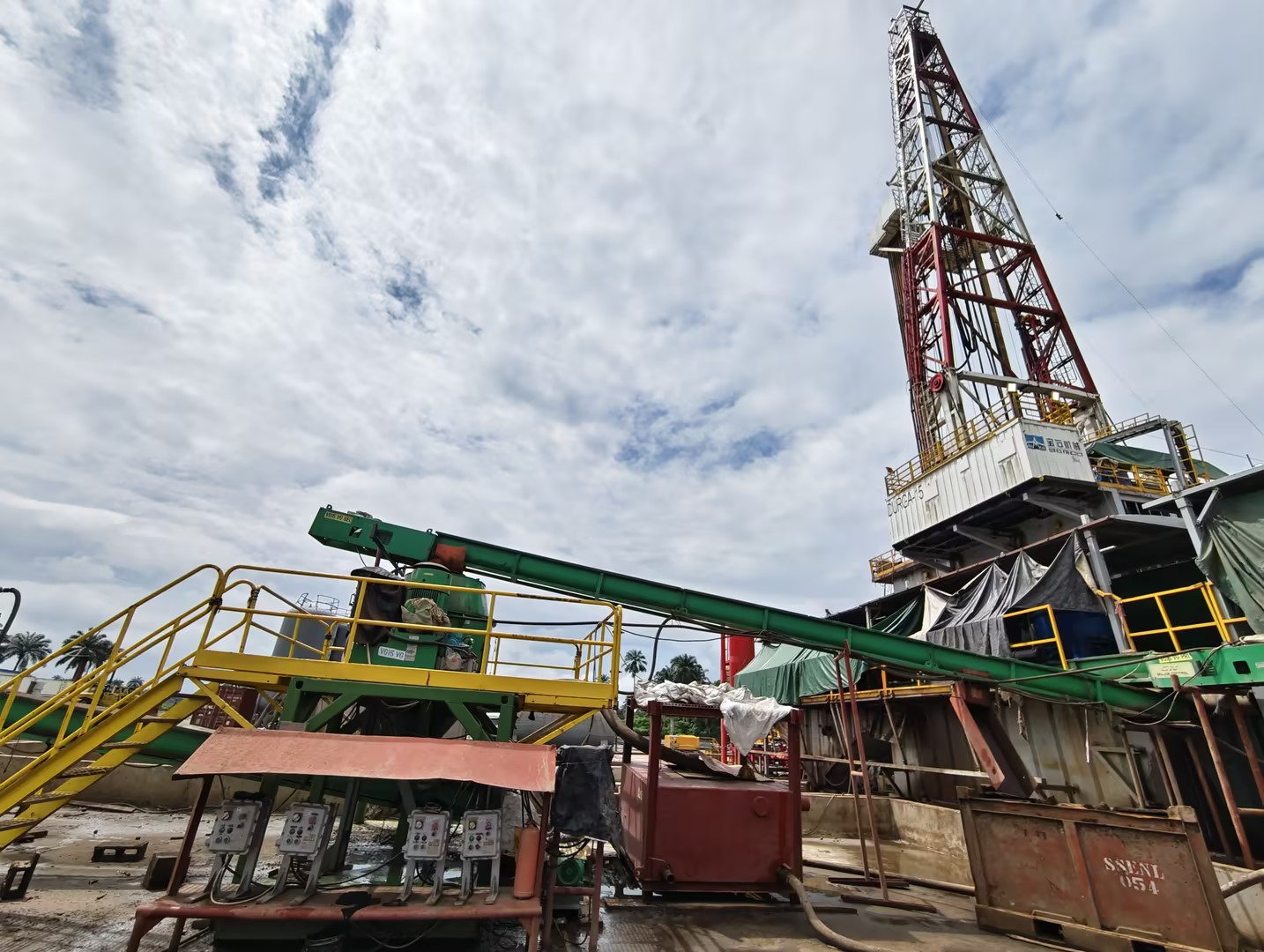

GN Decanter Centrifuge and Cuttings Dryer for Africa Drilling Company

We are pleased to announce the successful delivery and commissioning of a comprehensive drilling waste management system to a leading drilling company in Africa. This tailored solution, centered on GN's robust separation technology, is designed to enhance operational efficiency, maximize fluid recovery, and support responsible waste handling practices.

The core of this system features a powerful combination of GN's advanced solids control equipment:

Two (2) Units of GNLW363CD-VFD Decanter Centrifuges

At the heart of the liquid-solids separation process are the high-performance GNLW363 decanter centrifuges. Featuring a 14-inch (360mm) bowl with an industry-leading 3.5:1 length-to-diameter ratio and operating speeds up to 4000 RPM, this model delivers exceptional clarifying performance. Built for durability in demanding environments, its centrifugally cast duplex stainless steel bowl ensures structural integrity. Critical wear areas are protected with tungsten carbide hardened tiles on the conveyor, and replaceable ceramic/tungsten carbide inserts at both the feed and discharge zones. Furthermore, integrated Tungsten Carbide plows continuously clear the solids discharge area, preventing buildup and ensuring consistent operation. The use of premium SKF bearings throughout guarantees extended service life and reliable, low-maintenance performance, maximizing uptime between overhauls.

One (1) Unit of GNCD930G Vertical Cuttings Dryer

For final-stage drying of drilled cuttings from oil-based or synthetic-based fluids, the system includes the GNCD930G Vertical Cuttings Dryer. This unit employs high centrifugal force (up to 420G at 900 RPM) to efficiently separate residual liquids from solids. The process sees liquid forced through the stainless steel screen bowl, while the dried solids are conveyed upward by a tungsten carbide-protected scroll. This robust construction is essential for resisting abrasive solids and maintaining the precise scroll-to-bowl gap critical for optimal drying efficiency and long operational life.

Complete Supporting Package for Integrated Performance

To ensure the entire system operates as a cohesive and efficient unit, the delivery included all necessary ancillary equipment:

Centrifuge Feed & Cuttings Dryer Washdown Pumps: Specifically, the GNG Series Positive Displacement (Screw) Pumps are employed. These pumps are ideal for feeding decanter centrifuges, as their design transfers fluid without shearing or agitating the drilling mud. This maintains fluid properties and ensures steady, pulsation-free flow into the centrifuge, which is crucial for achieving peak separation performance. Constructed with stainless steel shafts and offering a full stainless steel body option, these pumps are built for reliability and corrosion resistance.

This deployment to Africa underscores GN's capability to provide not just individual machines, but fully integrated, site-ready processing systems. By combining high-G-force centrifugation with final-stage thermal drying and precisely matched pumping technology, we empower our clients to achieve drier solids, greater fluid recovery, reduced waste volumes, and more cost-effective, environmentally conscious operations.

GN remains dedicated to engineering reliable, innovative, and effective separation solutions for the global energy and environmental sectors.