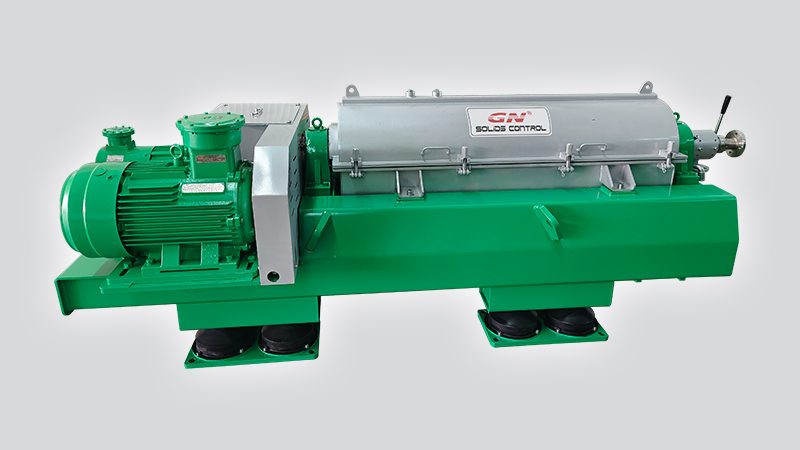

3 Phase Decanter Centrifuge

3 Phase Decanter Centrifuge

Categories:

Decanter Centrifuge.DESCRIPTION

-

GN 3 phase decanter centrifuge is used to separate two liquid phases from one solid phase at the same time. As is known, decant centrifuge principle of separation is by G force. Because of the different densities of the (immiscible) liquids and the solid , so all three phases can be discharged simultaneously using the GN 3 Phase decanter centrifuge. GN Solids Control design and manufacture three phase decanter in different bowl size include: 360mm, 450mm and 550mm.

However, to do the 3 phase separation, the solid phase must be the specifically heaviest phase and the two liquid phases should have different densities.

The structure and principle of the three phase decanter centrifuge are similar to the two phase decanter centrifuge. The difference is the way of the liquid discharged. There are two liquid phases in separation in a 3 phase decanter centrifuge. A higher density liquid phase is discharged under pressure, and the lower density liquid is discharged without pressure. Following is the principle drawing of the 3 phase decanter centrifuge.

GN 3-Phase Decanter Centrifuge Parameter

Model GNLWS-364 GNLWS-454 GNLWS-554 Type Continues Oil / Water / Solids Separation Bowl Dia 360mm 450mm 550mm Bowl Length 1567mm 1947mm 2347mm Capacity 5 m3/h 10 m3/h 15m3/h Max Speed 3986 RPM 3452 RPM 3123 RPM Max G Force 3200 G 3000 G 3000 G Diff. Speed 0-30 RPM 0-30 RPM 0-30 RPM Main Drive 22/30 KW 37/45 KW 55/75 KW Back Drive 7.5 KW 11/15 KW 18.5/22 KW Lubrication Grease Grease Oil Pump Oil Pump Size N/A or 0.37KW 0.37 KW 0.37 KW Feed Material Solids Less 10% and Particle Size less than 2mm The above specification and parameters for reference only. Bowl Assembly of 3 Phase Decanter Centrifuge

Applications For Three Phase Decanter Centrifuge

- Separation of oil sludge containing oil from refineries, oil ponds, etc.

- Extracting animal/vegetable fats and oils

- Starch manufacture for separating wheat starch and gluten.

- Oil Water and Solids separation.

- Coal tar treatment

- Biofuel production

- Lubricating oil additives

- Meat/poultry/fish (edible & inedible fats; yellow, white and brown grease)

- Edible oils (olive, palm, granola)