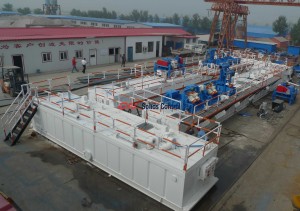

The NOV Brand Rapid Mud Tank System is a two-tank unit with a total active capacity of 620 barrels (total capacity of 800 barrels). This usually used for oilfield petroleum drilling.GN Solids Control also design and make such Rapid Mud Tank Unit completed with all necessary Solids Control Equipments.

General Specs for the Rapid Mud Tank System.

Equipment type:Two-tank, Rapid Mud Tank System

Total tank system volume*

620 bbl (at 12 in below mud rim)

Pill (slug) tank volume73 bbl

Maximum mud weight“18 lb/gal

Process capacity (nominal)1000 gal/min

Degasser capacity (nominal)700 gal/min

Flowline 10 in manifold with cement and active bypass

Some benifits of the Rapid mud tank system: Continue reading “GN & NOV Rapid Mud Tank System”