When referring to offshore drilling fluids management, usually remind us STEP OFFSHORE, which belongs to AKER SOLUTION, a very famous company. But they are not manufacturer.

In 2010, STEP Offshore appointed exclusive distributor for Derrick. STEP Offshore given exclusive right to sell premium solids control equipment and screens in Europe. Logistics infrastructure in place to satisfy the most demanding customer requirements. Pyramid Plus screen technology gives up to 200 percent more screen area.

For the offshore drilling fluids management, Derrick supply these main products: Dual Pool 600 shale shaker, Dual Pool 600 mud

cleaner, FLC 513, FLC 514, FLC 503, FLC 504, DE-CP Premium 250 Centrifugal Pumps, DE-7200 VFD Centrifuge, DE-1000 Series Centrifuges, similar as onshore drilling while suit for offshore environment.

GN Solids Control can supply similar products for offshore application. Choose the proper motors, marine explosion proof, concern more on the painting, also the control panels, and so on.

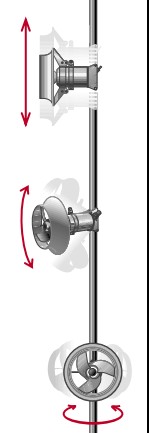

BEM703 shale shaker, which is balanced elliptical motion, is designed by Mr. Zhang in Southwest Petroleum University in 2009, and trialed in 2011 in one Chinese oilfield. Then we take it to the CIPPE 2011, this means it has been lead into the international market.

And it is very exciting that it is the highlight of all solids control equipment in the exhibition, we signed 2 contracts for similar system just in the booth.

For treating the oil drilling fluids, the balanced elliptical motion shaker is 20%-30% bigger than linear motion shaker, discharging speed is 10%-20% faster;For resisting the “screen stuck”, “screen paste” “horseshoe effect” ,the balanced elliptical motion shale shaker is much more effective.