GN Solids Control have exported 9 mud system to Australia from last year, for coal bed methane drilling and HDD (horizontal directional drilling). The feedback is very exciting. More and more Australian companies are going to buy from us. And we are going to attend the No-dig exhibition in October, 2011.

Coal Bed Methane Drilling Exploration in Australia

Although the presence of methane has been known ever since coal mining began, separate commercial production of CBM is a relatively recent step. This commenced in the USA in the 1970’s, and exploration for CBM in Australia began in 1976 in Queensland’s Bowen Basin when Houston Oil and Minerals of Australia Incorporated drilled two unsuccessful wells. In February 1996 the first commercial CMM operation commenced at the Moura mine in Queensland methane drainage project (then owned by BHP Mitsui Coal Pty Ltd). In the same year at the Appin and Tower underground mines (then owned by BHP Pty Ltd) a CMM operation was used to fuel on-site generator sets (gas fired power stations). The first stand alone commercial production of CBM in Australia commenced in December 1996 at the Dawson Valley project (then owned by Conoco), adjoining the Moura coal mine.

Coal Bed Methane Drilling Mud System

Very similar to systems for HDD, but higher required about the electricity. Now we are learning very well about this part, that is why we are competitive, our manager usually says. Very Thankful for the clients which are patient, and help us to know all these very well.

Here is a list of some exciting news, if you want to know more, kindly contact us.

2 Sets 500GPM Mud Recycling System with Hydraulic Jack up to Australia Brisbane

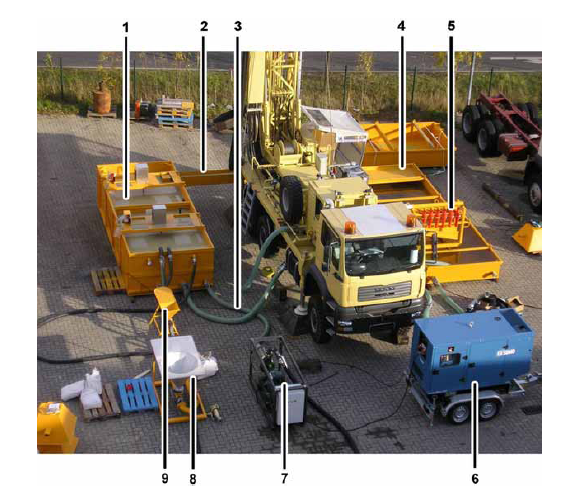

GN500 GPM Drilling fluid system for coal seam Methane and HDD

Auxiliary pump

Auxiliary pump