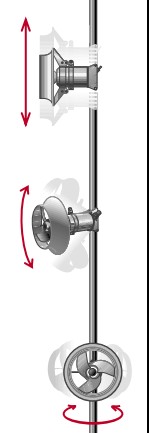

Submersible mud agitator is also used widely in oil & gas drilling, for the drilling work is usually complicated. To prevent

sedimentation, that is why we use mud agitator, but the suspend type is not usually suitable for all kinds of condition.

Drilling mud is composed of extremely small particles and has a thick consistency. Its settling velocity is therefore low, and sediment should not be a problem if the contents in a tank can be kept in motion. But, due to the combination of the irregular shape of tanks and the inefficiency of conventional mixing systems, sediment build-up is a timeconsuming and expensive problem.

Features and Advantages:

• No sedimentation – the agitator suspends the solids, counteracting the mud’s tendency to stratify.

• Full tank volumes – by preventing sedimenta-tion, the full volume of a tank will always be available, allowing for prolonged drilling opera-tions.

• No manual clean-out – ends time-consuming and expensive manual or mechanical removal of sediment.

• Problem-free pumping – with well-mixed drill-ing mud, problems are avoided when pumping the mud.

• Monitoring and control – we supply monitoring devices, for full operator control.

• Faster batch productivity – the combination of high turbulence and high flow results in fast batch turnover.

Applications:

Submersible, then it must be used in tanks, or something alike. Mud tanks in supply ships, drilling rigs, mud plants.

If you need more info., Contact GN.