Recently, GN Solids Control has a 1500 HP drilling rig solid control system successfully sold to projects in Africa. This achievement marks another solid step for GN Solids Control in the international market.

It is a full function solids control mud system includes extremely rich and advanced equipment. Among them, there are three shale shakers, model GNZS594J-SHBJ, which can efficiently perform solid separation work; 1 jet type vacuum degasser, model GNZCQ-1200, capable of effectively removing gases; There is also one designer, model GNZJ591J-M2SF, and one desilter, model GNZJ591J-M16NF, They play an important role in handling impurities and fine separation.

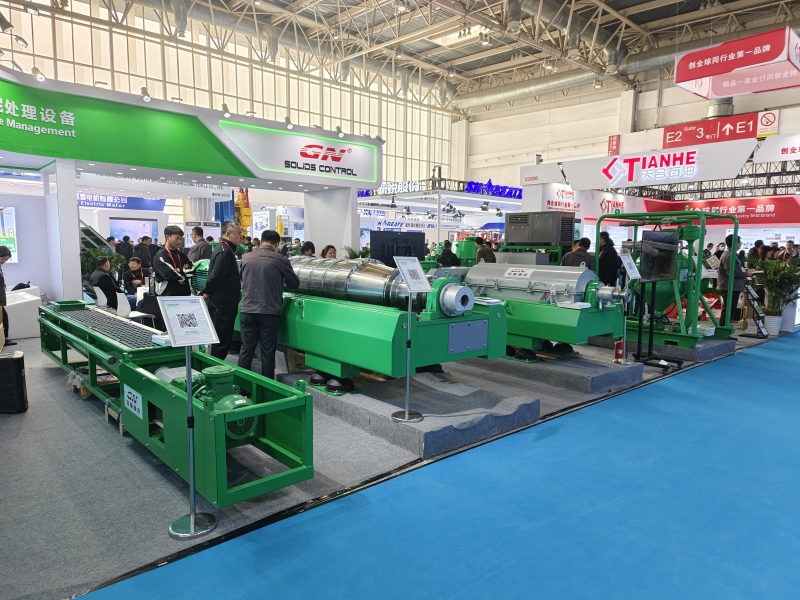

In addition, the system is also equipped with equipment such as variable pumps and mud agitators. The agitator can fully mix mud and other substances to ensure even mixing and maintain good performance, providing strong support for subsequent operations; The sand pump is responsible for extracting and transporting liquids containing solid particles, ensuring smooth fluid flow; The high-speed decanter centrifuge GNLW363D plays a crucial role in separating and purifying liquids through high-speed rotation, further improving the operational efficiency and quality of the entire solid control system.

The role of expanding the solid control system of the 1500 horsepower drilling rig produced by GN Solids Control in petroleum drilling systems.

The 1500 horsepower drilling rig solid control system produced by GN Solids Control plays a crucial role in oil drilling systems. This solid control system is like a solid guardian of oil drilling operations, providing strong support for the entire drilling process with its powerful functions.

It can efficiently separate and treat a large amount of solid waste and impurities generated during the drilling process, ensuring the cleanliness and stable performance of the drilling fluid, and maintaining the smooth progress of drilling operations. Through precise control and operation, it effectively reduces the solid content, avoids the wear and damage of solid particles to drilling equipment, extends the service life of equipment, and reduces maintenance costs.

At the same time, the solid control system can also precisely adjust the various parameters of the drilling fluid to meet the needs of different formations and working conditions, ensuring the safety and reliability of drilling. It is like the core hub of the entire petroleum drilling system, coordinating the operation of various links, enabling petroleum drilling operations to be carried out in a more efficient, stable, and safe manner, laying a solid foundation for the smooth exploitation of petroleum resources, and contributing an undeniable force to the sustained development of the petroleum industry.