In the field of municipal sewage treatment, efficient equipment and advanced technical solutions are essential. Recently, GN Solids Control’s three GNLW654-VFD sludge dewatering centrifuge units were successfully applied to municipal sewage treatment projects in North African.

1. GNLW654-VFD dewatering centrifuge: a sewage treatment solution with excellent performance

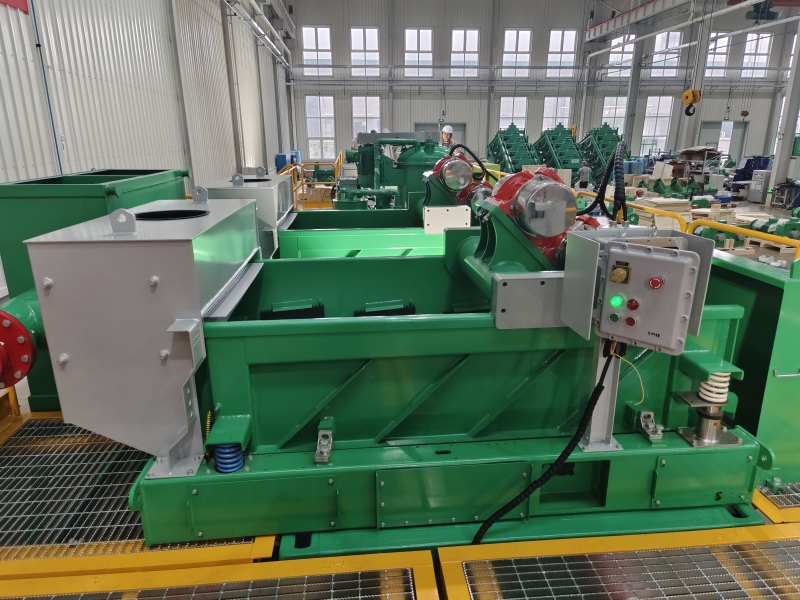

These three GNLW654-VFD dewatering centrifuges played a core role in the project. They adopt advanced design and manufacturing processes and have excellent dewatering performance. The GNLW654-VFD decanter centrifuge can quickly and effectively separate the water from the sludge, greatly reducing the water content of the sludge, and providing convenience for subsequent treatment and disposal.

The centrifuge is equipped with temperature and vibration sensors to monitor the operating status of the equipment in real time. The temperature sensor can detect whether the equipment is overheating in time to avoid damage to the equipment due to high temperature. The vibration sensor can detect the vibration of the equipment. Once abnormal vibration occurs, timely measures can be taken to adjust it to ensure the stable operation of the equipment. This intelligent monitoring system improves the reliability and safety of the equipment and reduces the probability of equipment failure.

In addition, the GNLW654-VFD dewatering centrifuge is also equipped with four variable frequency control cabinets, which control the main motor, auxiliary motor, slurry supply pump and dosing metering pump respectively. The variable frequency control technology can flexibly adjust the operating parameters of the equipment according to actual needs to achieve the purpose of energy saving and consumption reduction. At the same time, it can also improve the operating accuracy and stability of the equipment to ensure the stability and reliability of the sewage treatment effect.

2. 6500L flocculation dosing device: Provide strong support for sewage treatment

In this project, 1 set of 6500L flocculation dosing device is also equipped for the centrifuge dewatering treatment. The device comes with a screw dosing metering pump, which can accurately control the amount of flocculant added and improve the effect of sewage treatment.

The flocculation dosing device plays a key role in the sewage treatment process. It adds flocculants to make the tiny particles in the sludge condense into larger particles, which is convenient for the centrifuge to dewater. The 6500L large-capacity design can meet the large-scale sewage treatment needs of the project, while the screw dosing metering pump has the characteristics of accurate metering and stable operation, ensuring that the amount of flocculant added is always kept at the best state.

GN Solids Control has been committed to providing high-quality solid control equipment and sewage treatment solutions to customers around the world. The successful application in the municipal sewage treatment project in North African countries once again proves the technical strength and product quality of GN Solids Control.