Desilter is the third phrase solids control equipment. It is usually used following shale shaker, desander.

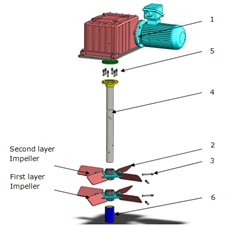

Desilter is usually combined of a under fluid shale shaker and desilter hydrocyclone assy.

Under fluid shale shaker:

For a better separation result, many users will choose a under fluid shale shaker under desilter hydrocyclone assembly.

Solids phase discharged from desilter cyclone can be further separated by shale shaker. Useful mud falls into tank for recycling.

Hydrocyclone Assy:

4’’ hydrocyclone is most widely used for desilter in oil & gas drilling field. And quantity can customized per clients requirements, vary from 4 each to 24 each.

Advantages of GN brand desilter

As world top solids control manufacturer, GN Solids Control have following strong points compare with othes:

1) Big underflow shale shaker: GNZS752 for better separation and compact design with small footprint of non-underfluid model

2) 100% Polyurethane (PU) ,material for desilter cnoes with longer using lift, and interchangeable with Derrick.

3) Shut off stainless steel ball valve available for option on each cone inlet permit individual cone removal and inspection without interrupting operation of the desilter

4) Tangentially blended into the cone entry as a narrow rectangle to minimize turbulence in the upper section of the cone, allowing the solids to move quickly to the cone wall.

5) Flexable fast connection are available for user friendly assy.