Solids control equipment are widely used in mining industry for mining dewatering. In about last year, we give a solution for slime dewatering in mining. Here is the Q&A of Slime Dewatering System.

For a good solution, usually we need to know:

1) The particles, it is better if we can have a curve to show how many bigger ones, how many smaller ones.

2) What are you aim to, get the clean water for environment friendly, want some of the particles for economy purpose?

3) Sometimes density and viscosity of the drilling fluid is needed.

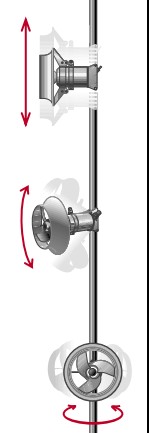

As shown in the picture, we choose our GNZS83-2 two panel linear motion shale shaker, ZQJ100s with PU hydrocyclones. Then we can get mixed water with particles less than 15 microns. Then if still need cleaner water, we can add decanter centrifuge.

| Thi is a system for hydromining to Turkey, we also customized kinds of system as required. |