Waste and pollution management approaches can be described as strategies. Solids control- drilling mud system is one part of it. At the municipal level these strategies traditionally have relied on disposal practices (predominantly landfilling and incineration), whereas industry has employed intermediate steps of treatment and stabilization of the more hazardous wastes.

Industry strategies are based on end-of-pipe treatment technologies, which are more appropriately referred to as control strategies, meaning their aim is really to control emissions and wastes to within legally allowable limits of discharge. Both strategies have two disadvantages:

1. They require ongoing costs that are associated with operations and maintenance and with use of energy, and they carry many hidden and indirect costs and liabilities.

2. Releases of infectious, toxic, and hazardous components to the environment continue for many years, posing long-term health risks to the public and endangerment to the environment simply because waste forms are only transformed and not entirely eliminated or completely immobilized.

Waste/pollution management strategies based on prevention strive to eradicate both of the above disadvantages because they eliminate the pollution or waste at the source. They tend to be only partially successful in reducing the first isadvantage because in a number of cases, P2 strategies rely on technology investments which have OM&R (operation, maintenance, and repair costs) as well as other ongoing costs (e.g., labor, energy). But in general, when properly implemented, they are more cost effective than disposal and treatment technologies. Minimization strategies tend to reduce the risks associated with the second disadvantage, but may also offset some of the costs and liabilities noted with the first disadvantage. Continue reading “Solid Waste Management Introduction”

Author: admin

Shale Shaker for NO Dig 250 ton Drilling Rig

Here we suggest mud recycling system especially the shale shaker for drilling rig250, as the name suggests, offers 250 tonnes.

Mur Recycling System for Rig 250/90

To get the best performace of no dig drilling rig, we need high performance mud recycling system to process drilling fluid at 800gpm.

It comprises 2 GNPS703 shale shaker for primary screening, and a GNPJ703 mud cleaner complete with two 10″ de-sander cones and 12 deisilter cones for de-sanding and de-silting. All these equipments are mounted one tank to save space. Usually 12meters long with 26 cubic meters net storage.

Balanced Eliptical Shale Shaker

With the most famous professor in China from Southwest Petro University, we developed our own model shale shaker.

GNZS852, GNZS703, GNPS703 are our updated shaker from this year, after testing and feedback from our clients, this is a big step and successful step.

Balanced elliptical shaker is more compact and more efficient. See more about GNPS shale shaker.

Coal Bed Methane Drilling Mud System to Australia

GN Solids Control have exported 9 mud system to Australia from last year, for coal bed methane drilling and HDD (horizontal directional drilling). The feedback is very exciting. More and more Australian companies are going to buy from us. And we are going to attend the No-dig exhibition in October, 2011.

Coal Bed Methane Drilling Exploration in Australia

Although the presence of methane has been known ever since coal mining began, separate commercial production of CBM is a relatively recent step. This commenced in the USA in the 1970’s, and exploration for CBM in Australia began in 1976 in Queensland’s Bowen Basin when Houston Oil and Minerals of Australia Incorporated drilled two unsuccessful wells. In February 1996 the first commercial CMM operation commenced at the Moura mine in Queensland methane drainage project (then owned by BHP Mitsui Coal Pty Ltd). In the same year at the Appin and Tower underground mines (then owned by BHP Pty Ltd) a CMM operation was used to fuel on-site generator sets (gas fired power stations). The first stand alone commercial production of CBM in Australia commenced in December 1996 at the Dawson Valley project (then owned by Conoco), adjoining the Moura coal mine.

Coal Bed Methane Drilling Mud System

Very similar to systems for HDD, but higher required about the electricity. Now we are learning very well about this part, that is why we are competitive, our manager usually says. Very Thankful for the clients which are patient, and help us to know all these very well.

Here is a list of some exciting news, if you want to know more, kindly contact us.

2 Sets 500GPM Mud Recycling System with Hydraulic Jack up to Australia Brisbane

GN500 GPM Drilling fluid system for coal seam Methane and HDD

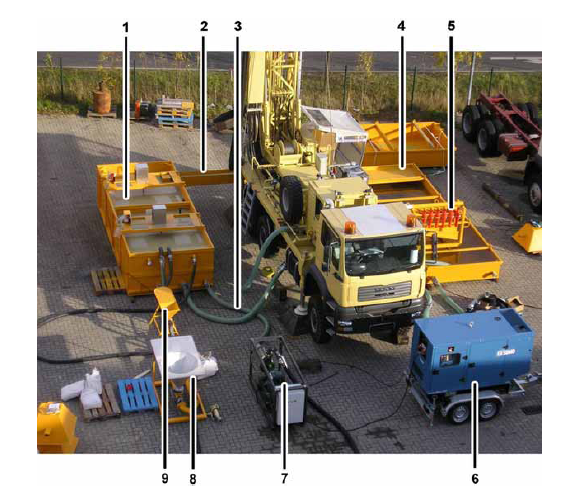

Mud Conditioning System for Rotary Drilling

The auxiliary units of this system must be ordered separately. They are no components of the rotary drilling rig and, thus, are not included in its scope of delivery. Auxiliary units include several components that are detailed on the following pages: Auxiliary pump

Auxiliary pump

Hopper

Mud tank

Mud ditch

Desander

Hoses and hose couplings

In individual cases the arrangement may be different, depending on the local usage site and conditions.

Filter Press in Mud System

Filter press know as an equipment in environment protection, (Filter Press wiki), it is a separated system. Referring to mud cleaning system or mud recycling system for dealing with drilling waste of construction, or HDD,or alike. “We need clean water.” So a filter press seems better.

As one client told us: We have the mud pit, so not like your system working continuously. It is a big one, and do not working with other equipment as systems, no logical connections. It can handle big particles, but if the particle smaller, it is better.

We need a highly efficient, compact, plate & frame filter press dewatering filter press device for separating solids from liquid slurries in the form of compressed cake. Its major components are a structured framework, plate and frame dewatering filter press system and filter cloth (shown with optional sludge carts).

If you have any more questions, Here is a list of questions about our filter presses that we commonly receive.

To solve the customers problem, we supply one updated GNZS8752 shale shaker, one GNZJ852 mud cleaner, and one jet mud mixing equipment. After the desander, it is the filter press, one plate & frame filter press.

Water Well Drilling Mud System for SALE

After coming back from exhibition from Brazil, Russia, GN now is going to attend the exhibition in Argentina. We also are considering to attend Mining Conference in Mongolia on 8-9 September, 2011.

Water Well Drilling Mud System for SALE!

We are going to take one complete water well drilling mud system, so drilling contractors, or end users can understand more about our products. The one who buy the mud system for showing will get a special discount, free transportation, or other conditions for discussion.

GN Solids Control have exported to Mongolian several water drilling mud systems, we have cooperate very well with schramm drilling rig company, they are very happy with our mud systems.

Major Drilling in Mongolia also bought one mud system from us. It is working very well, this is the feedback.

It is a good chance to try our products, and then if you buy again, you will know, GN Solids Control always supplying high quality products, for exhibition or not, it will also a better exhibition in your working site.

Fast Moving Mud System from GN

“FAST MOVING” is becoming a more and more important factors for drilling system, especially for small and compact ones. Then rigs, mud pumps, and mud systems, all putted onto a trailer.

When we put our system in CIPPE 2011, we just put the mud system on the trailer, for fast moving, and keep it compact. Then the clients are very excited to say, wow, GN Solids Control is going to supply fast moving mud system.

When we put our system in CIPPE 2011, we just put the mud system on the trailer, for fast moving, and keep it compact. Then the clients are very excited to say, wow, GN Solids Control is going to supply fast moving mud system.

Yes, we are! But we are designing and testing them, it needs some time to say “hello, world”. As people know, we insist our own design, and produce systems for our clients with high quality. Keep tune, you will get the exciting news.

Now we have produced 2 mud system, with hydraulic jet legs, for an Australian client.

While happy to see that, other clients are also very interested in this.

At the same time, a really fast moving mud system, which is mounted on a trailer, as we have known from other foreign mud system. And one customer are going to buy the first set.

trip tank manufacturer

Trip tank is part of whole drilling mud system, usually a small metal tank with small capacity about 20-40 bbls with 1 bbl divisions inside and it is used to monitor the well. The trip tank is utilized to determine well condition in order to see if the well is still under static condition.

How the trip tank work?

While Tripping Out of Hole (TOH), a trip tank pump will circulate mud into a bell nipple in order to keep the hole full all the time and the over-flow mud will return back to the trip tank. Once every stand is pulled, the mud volume in the well will decrease because the drill pipe is pulled out of hole. Since the trip tank pump is always run while tripping, the annulus will be full all the time.

Trip tank manufacturer in China:

Beside is the ZJ70 drilling mud system, manufactured by GN Solids Control, the client is a famous Indian company, they repeat 3 orders for whole system.

GN Solids Control can supply the whole drilling mud system, trip tank included.

For the whole trip tank, it usually contains one mud agitator, one or two centrifugal pump, and GN Solids Control supply high quality products.

Gas Bustor to Pakistan

In the end of May, we exported a gas bustor to Pakistan, the Poland company’s office repeat an order for gas bustor. This time they also need a elevating gas bustor to satisfy various comoplicate site conditon, more flexible.

A simple separator vessel used to remove free or entrained gas from fluids circulated in the wellbore, such as mud used during drilling operations. The gas buster typically comprises a vessel containing a series of baffles with a liquid exit on the bottom and a gas-vent line at the top of the vessel. It captures and separate large volume of free gas within the drilling fluid. If there is a “KICK” situation, this vessel separates the mud and the gas by allowing it to flow over baffle plates. The gas then is forced to flow through a line and vent it to a flare. A “KICK” situation happens when the annular hydrostatic pressure in a drilling well temporarily (and usually relatively suddenly) becomes less than the formation, or pore, pressure in a permeable section downhole, and before control of the situation is lost. It is always safe to design the mud/gas separator that will handle the maximum possible gas flow that can occur.

High Quality Gas Bustor Supplier

GN Solids Control supply high quality gas bustor all over the world. As an API & ISO certified company, GN Solids Control always choose top quality material, Yuanda valve, Seismic pressure gauge.

Shale Shaker for Offshore Project

Shale shaker is important for offshore drilling mud management, offshore waste management, and not same as onshore shakers, it has higher requirements. GN Solids Control can supply both elliptical and linear motion shale shaker for offshore project.

Shale shakers are essentially vibrating sieves that remove drill cuttings. The basic designs feature large wire cloth screens that shake or vibrate drill cuttings off the screens as the fluid flows back into the mud system and down the well bore. The challenge for drilling crews is to run the screens as finely as possible while still maintaining an efficient flow rate. It’s a difficult but important balancing act, since controlling solids in the drilling fluid is crucial for controlling costs.

GN Solids Control totally understand this, and emphasize the application, focus the user friendly. So GN always choose the top quality material from all over the world.

For offshore project, we use marine explosion proof motor, (Explosion proof rate dⅡBT4), shaker surface is coated with heavy anticorrosive paint.

Excited to broadcast that now we are going to export 2 mud system to America, and Halliburton buy products from us. So if you are interested in our shaker for offshore project, contact GN now.