Vertical rotating drilling rig is the normal machine used in piling project. During the drilling process, in order to protect the inner wall of the drilling hole and speed up the process, the operator always chooses to use drilling mud. Then here comes another problem how to reduce cost of the drilling mud thereby to reduce the cost of drilling. The solution is to use mud recycling system to make the drilling mud reusable.

The purpose of the mud recycling system is to remove the large size solid particles in the drilling mud by several separation machines. In regards to the mud recycling system for piling project, it could be a very compact design as separation process is not so complex as that for oil gas drilling. GN solids control is one of the most experienced separation solution providers who could provide the mud recycling system for almost all the industries will use it. GN already developed the standard mud recycling system especially for the piling project.

Strictly speaking, the mud recycling system used in piling should be called de-sanding unit as the drilling depth is normally shallow and most of the solid particles are sand. A de-sanding unit would be enough for processing the separation to get the expected reusable drilling mud.

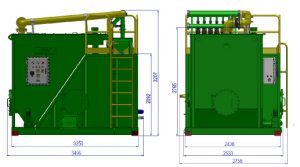

GN’s de-sanding unit is a compact structure 2 steps separation system. The main equipment in this de-sanding

unit is combined with a 2 layers shaker and cyclone manifold. The double layers shaker is used for coarse solids separation by the under layers and the upper layer screen is for drying the slurry discharged from the cyclone unit. The tank under the shaker unit is used to store the drilling mud. One centrifugal pump is installed in the system for transferring the mud to the cyclone unit for sand separation.

This de-sanding unit could be connected with extra mud tank for larger capacity mud storage. The operators can also equip a jet mixing unit to make an self-contained mud recycling system for other drilling project like HDD and water drilling.