Articles

Desander

Mud Desander

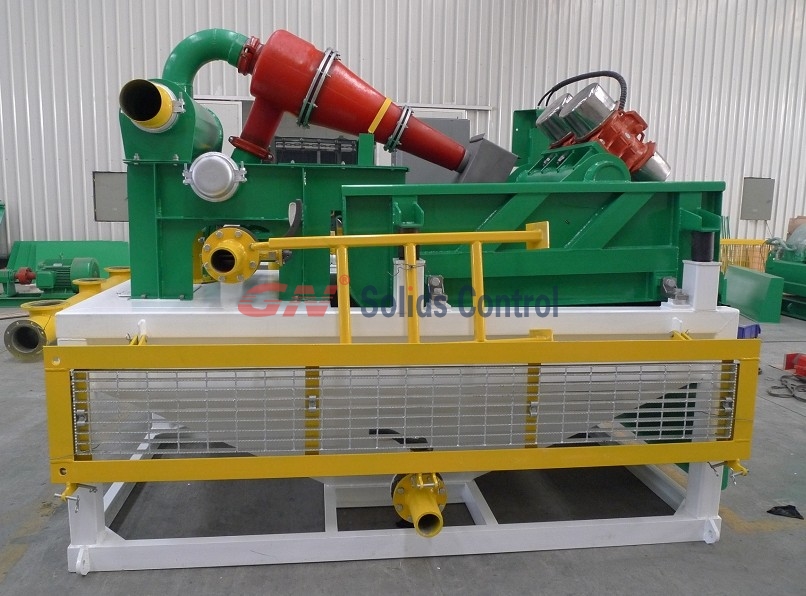

Following is desander for two different industry and system, Part 1 two desanders are for oil gas drilling, CBM drilling mud solids control. Part 2 desander system with mud tank is for contruction operation for No dig, Bored Pile drilling deander for bentonite recycling.

Part 1: Desander for Oil Gas drilling & HDD

Desander Options for different Application

| Desander Types | Desander Discription |

|

|

Type: Desander without downstream drying shale shaker Model: GNWS-2S / GNWS-3S Desander Application: For oil gas drilling un-weighted drilling mud. Features: Small footprint, economic choice, no consumable screens. Result: Wet cuttings, not recommended for Weighted mud and drying solids. |

|

|

Type:Desander with GNZS752 Series Mini Shale Shaker Screen Area:1.35㎡ Model: GNZJ752E-1S / GNZJ752E-2S Desander Application: For oil gas drilling small drilling rig , CBM drilling, HDD, Water Well drilling. Features: Small footprint, economic choice, acceptable drying solids. |

|

Type: Desander with GNZS703 Series 3 Panel Shale Shaker Screen Area:2.6㎡ Model: GNZJ703E-D2S / GNZJ703E-3S Desander Application: For oil gas drilling big drilling rig , large HDD rig, Tunneling Boring Machine etc. Features: Big capacity,, drying solids. |

GN Desander Technical Parameters

| Model | GNZJ752E-1S/2S | GNZJ703E-D2S | GNZJ703E-3S | GNWSE-2S/3S |

| Capacity | 120/240m3/h | 240m3/h (1056GPM) | 360m3/h(1584GPM) | 240/360m3/h |

| Desander Size | 10 Inch | |||

| Desander Qty | 1/2pcs | 2pcs | 3pcs | 2/3pcs |

| Working Pressure | 0.25~0.4Mpa | |||

| Feeding Size | 6 Inch | |||

| Output Size | 8 Inch | |||

| Bottom Shale Shaker Specs | ||||

| Shaker Model | GNZS752E | GNZS703E | N/A | |

| Vibration Mode | Linear Motion | |||

| Vibration Motor | 2×0.75Kw | 2×1.72Kw | ||

| Angle Adjust Motor | N/A | 0.55Kw | ||

| Screen Qty | 2pcs | 3pcs | ||

| Screen Size: L×W | 750×900mm | 700×1250mm | ||

| Screen Area | 1.35m2 |

2.63m2 |

||

| Adjust G Force | ≤7.1G | ≤7.5G | ||

| Vibration Amplitude | 3.92~5.62 | 4.14~5.96 | ||

| Deck Angle Range | +2° | -1°~+5° (Eletric & Mechanical) | ||

| EX Standard | ExdIIBt4 / IEC EX/ ATEX | |||

| Weight (Kg) | 1048/1105 | 1888 | 1964 | 502/559 |

| Dimension (mm) | 1674×1707×1719 | 2419×2113×1608 | 2419×2113×2126 | 2193×900×1511 |

GN Mini Mud Cleaner(Desander)

The GN Mini Mud Cleaner is innovative products for drilling fluids cleaning. The traditional desander desitler without Shale Shaker is only available for unweighted drilling mud.The traditional mud cleaner is oversized for some applications,and the mud cleaner is relatively more expensive. The innovative GN Mini cleaner is an ideal option for both weighted and unweighted drilling mud with the most cost effective solution for drilling. Further more, the GN Mini Cleaner is the best choices for small mud system for HDD,CBM, water well drilling, mining exploration industry etc.

Desander for Oil drilling mud

Hydrocyclones is also called cyclone separator.Hydrocyclones consist of desander(10 in. cone) and desilter(4 in. cone)are drilling rig equipments with a set of hydrocyclones that separates sand and silt from the drilling fluid. Desander is installed after shakers and degasser but before desilter. Desander removes those abrassive solids from the drilling mud which cannot be removed by shakers.

Desander, as stated earlier, have no moving parts. The larger the internal diameter (ID) of the desander is, the greater the amount of fluid it is able to process and the larger the size of the solids removed. Desander (10 in.cone) are able to remove roughly 50 percent of those solids within the 40-50 micron range at a flow rate of 500 gallons per min (gal/min), while desilter (4 in. Cone) are able to remove approximately 50 percent of those solids within the 15-20 micron range at a flow rate of 60 gal/min. Micro fine separators are able to remove around 50 percent of those solids within the 10-15 micron range at a flow rate of 15 gal/min. Desander is typically positioned next-to-last in the arrangement of solids control equipment, with decanting centrifuge as the subsequent processing unit. Desander are preceded by gas busters, gumbo removal equipment (if utilized), shale shakers, mud cleaner (if utilized) and vacuum degasser.Desander is widely used in oilfield drilling.

Part II: Desander Plant for Bored Pile and TBM

|

|

Bored piles are cast in place cylindrical piles excavated either by use of rotary equipment operated augers , buckets, under static drilling fluid or large drill bit (for hard rock) with reverse circulation.The reason to use desander unit is that Bored piles installed in common soil with the presence of water table, generally require the use of a short temporary steel casing and a drilling fluid as static suspension to provide support to the surrounding soil while excavating the pile and until complete backfill of the pile excavation with concrete, in order to prevent cave-in of the excavation and destabilizing the surrounding soil formation.GN Bored Pile desander is to separate the sands from the drilling fluids and recycling the drilling fluids for use.

Read more for GN Desander

GN is a China desander manufacturer with location in Houston, USA, and partners around the world.,solids control system desander,drilling fluids,drilling fluids desander..Your best solids control service!Your best Hydrocyclone Desander for drilling mud circulation system.

- Desander Desilter and mud gas separator to Argentina

- GN Desander Desilter

- Hydrocyclone Desilter

- Mud desander for HDD

- Desander manufacturers company list

- Five Sets of Desanders and Desilters for Kuwait Clients

- Shale Shaker Desander & Desilter to Indonesia