De-sander is very popular equipment used in solids and liquid separation processing. It always contains cyclone unit and steel frame. With different diameter of the cone body, this cyclone unit could separate the solid particles with different sizes. GN’s de-sander is using 10 inch cyclones which could remove the solids size down to around 45 microns.

GN’s de-sander unit is used in drilling industry to separate the drilling cuttings from the drilling fluids. Traditional de-sander units don’t have the under drying shaker for maximum recovery of the drilling fluids liquid, thus a large amount of valuable drilling fluids was lost. However, this type de-sander and even the de- silter unit are very simple structure and cost effective.

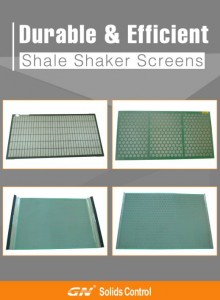

To make the discharged solids much dryer, GN prefer to suggest choosing the de-sander unit with a under drying shaker which could recycle much more drilling fluids. This could reduce the waste discharges to environment and the cost on drilling fluids materials. GN has a de-sander model with under drying shaker of 2 layers screens panel. This unit is functioning as both primary shale shaker and de-sander unit. The drilling fluids gets into this de-sander unit via the mud distributor pipe and then flow on the bottom layer screen firstly for primary solids control. Liquid gets through the screen mesh and falls down to the under located mud tank. Large size particles will be discharged out of the shaker. And then the liquid will be transferred by a centrifugal pump unit to the de-sander cyclone unit for fine solids separation. The mixture of liquid and solids discharged from the cyclone will come to the upper layers screen for drying processing. Here, to prevent the damage of screen mesh resulted by the strong impact force of solids discharged out from the cyclone unit, GN designs small buffer box to cover the outlet of the cyclone. This buffer box is small enough to make the unit more compact.

GN’s double-layer screen panel shale shaker can also be used as only primary shaker for much fine solids separation. Besides de-sander unit, de-silter unit can also use this type shaker as drying shaker.