Vertical cuttings dryers and decanter centrifuges are core processing equipment used downstream of the drilling mud solids control system. After the shale shakers, desanders, desilters, and mud cleaners separate the coarse and medium solids from the drilling fluid, a significant amount of fine solids and liquid remains trapped in the drill cuttings. To meet environmental regulations, reduce drilling waste volume, and recover valuable drilling fluid, further treatment of these drill cuttings is required. Vertical cuttings dryers, together with high-speed and low-speed decanter centrifuges, play a critical role in achieving this objective.

The vertical cuttings dryer is primarily designed to treat drill cuttings discharged from shale shakers when drilling with oil-based or synthetic-based mud. By utilizing high-speed centrifugal force, the dryer effectively removes residual liquid from the cuttings, significantly reducing oil-on-cuttings (OOC) and producing drier solids suitable for disposal or further handling.

Meanwhile, decanter centrifuges are used to process the liquid phase recovered from the dryer, as well as overflow from the solids control system, enabling fine solids separation and efficient recovery of drilling fluids. High-speed centrifuges focus on ultra-fine solids removal, while low-speed centrifuges are applied for barite recovery and density control, ensuring optimal mud performance and cost efficiency.

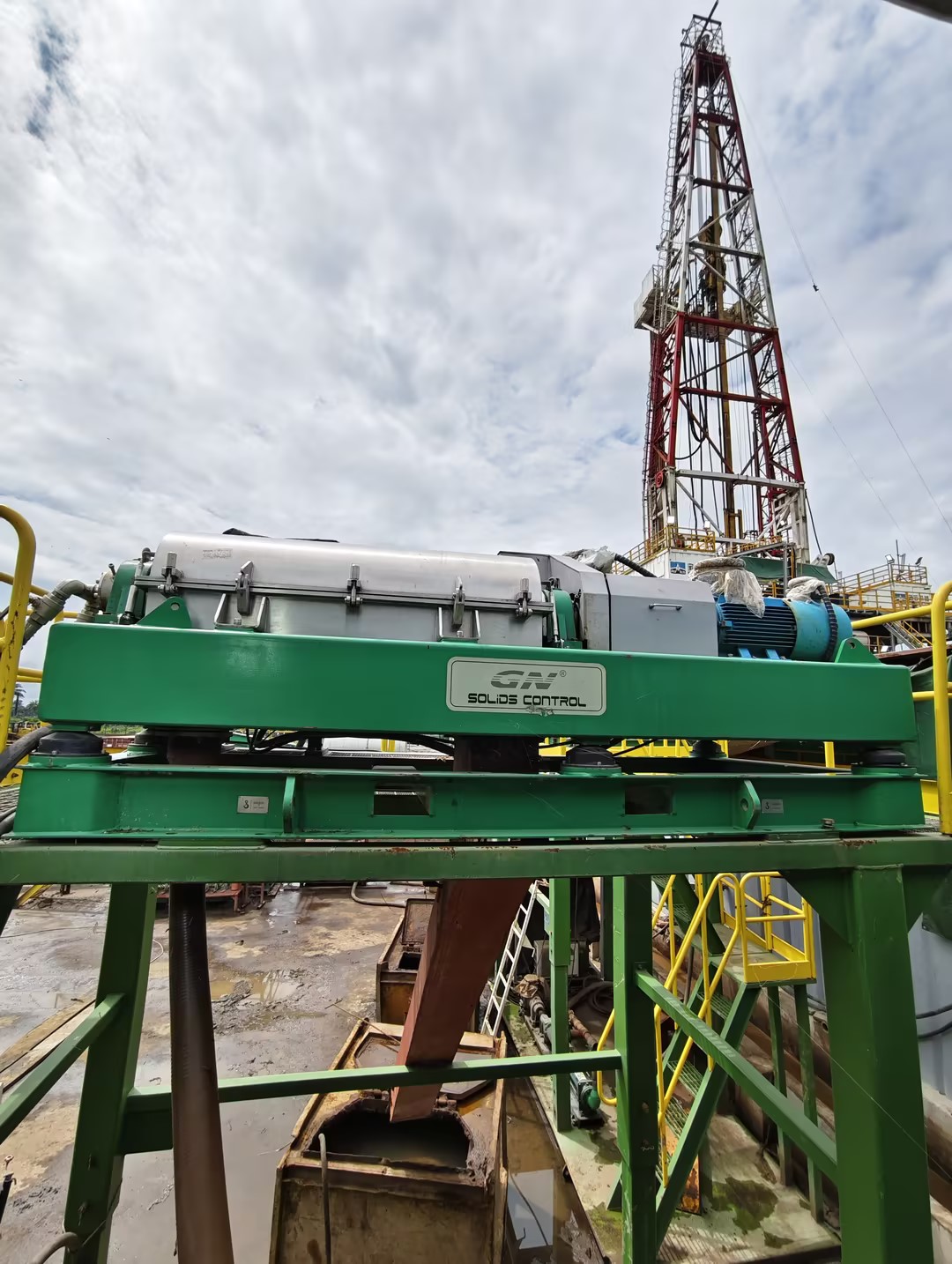

GN Solids Control offers a complete range of high-quality vertical cuttings dryers and decanter centrifuges designed to meet the diverse technical, operational, and regulatory requirements of different markets worldwide. The equipment is engineered with robust mechanical design, wear-resistant materials, and reliable control systems to ensure stable operation in harsh drilling environments.

Recently, GN Solids Control successfully delivered one (1) vertical cuttings dryer model GNCD930G and two (2) variable-speed decanter centrifuges model GNLW363D-VFD to an African drilling company. The decanter centrifuges are equipped with electrical variable frequency drives (VFD), allowing precise adjustment of bowl speed and conveyor differential speed. This flexibility enables the centrifuges to adapt to various applications, including fine solids removal, barite recovery, and fluid clarification, under different mud types and operating conditions. The supplied system provides efficient cuttings treatment, reduced environmental impact, and improved overall drilling fluid management for the project.