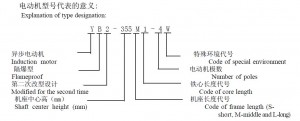

In oil & gas field, have to use explosion proof motors in hazardous areas, and in China, usually choose YB2 series. And China also have a lot of world famous motor manufacturers.

Though some world famous motors like ABB, WEG, also have office in China, and Siemens also have invent in Siemens Beide, now we are going to introduce some local companies. Also no leeson, Cantoni group.

Nanyang Explosion Protection Group Co. Ltd (hereafter indicated as CNE) locates in Nanyang city, Henan province, is one of the largest scientific research and production base of explosion-proof motors in China, the national export base for electro-mechanic products, and the national innovation enterprise as well as the chairman member of Ex motors branch of CEEIA.

Jiamusi Electric Machine Co., Ltd

JEM as the biggest Special motor factory in China was founded in 1937 in Shenyang city. In 1950 it was moved to Jiamusi city. In 2008, the company has established the management concept for modern enterprise and carried out the reformation in all aspects, thus forming a new style stock company. He manufactured the first Ex motor, crane and metallurgical motor axial-flow local fans and canned motor in the history of China.

Other local brand like Hengli, Pinxin, is also very famous supplier.

– High shear mixing, aids chemical and solids addition.

– High shear mixing, aids chemical and solids addition.