GN screw press dewatering unit is designed and made to treat sludge and sewage waste water. GN screw press dewatering machine is widely used in sewage treatment projects of municipal, aquaculture, food, starch, oil, pharmaceutical, chemical, paper, leather and other industries.

GN screw press dewatering unit is a kind of economic and environmental friendly sludge dewatering treatment product. It is a new type of sludge extrusion dewatering equipment by using the principle of screw extrusion, through the strong squeezing force generated by the change of screw diameter and screw pitch, and the tiny gap between the floating ring and the fixed ring, to realize solid-liquid separation.

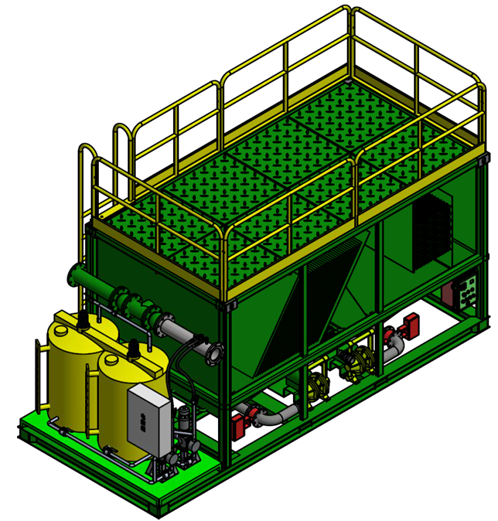

GN dewatering screw press unit includes below items:

1.PLC Smart control electrical panels for automatic control.

2.Chemical enhancing dewatering system for mixing and dosing flocculants into the waste water, slurries or sewage.

3.Sludge thickening and dewatering device

4.Liquid collecting tank to receive the recovered water from the screw press treatment.

GN dewatering screw press unit is with automatic control technology, which can mix and enhance flocculants automatically. After chemical enhancing, the screw dewatering press unit can running continuously to complete the sludge thickening and squeezing, finally return or discharge the collected filtrate liquid.

Besides dewatering screw press unit, GN Solids Control also makes automatic tank cleaning system. GN system is running automatically after preset parameters of the control panel. By adding the right tested chemicals, operators can achieve a satisfied liquid separation result. It can save time and save water in this case to further save cost. Some users of automatic tank cleaning system mentioned that, before without the automatic tank cleaning system they took 4 ~ 5 workers to clean one tank with 4-6 hours, now they just need 2 workers to clean one in 2-3 hours. It saves 80% man power and operation time.

If clients could share some technical demands, GN Solids Control is willing to check with engineering team and offer a customized solution to suit for clients; projects.