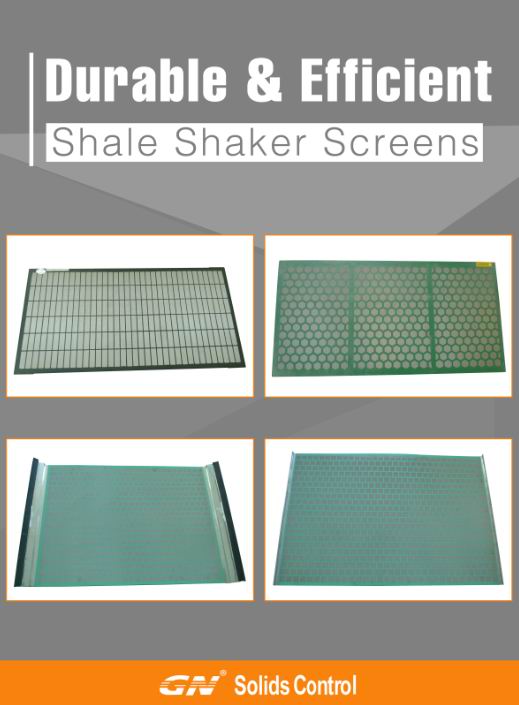

GN solid control is an internationally renowned manufacturer of solid control equipment and vibration screens. Well-known Chinese and foreign GN solid control trademarks have been well received by our customers. Our company’s products have been well applied in most of the world’s oil and gas drilling sites. Many world-class oil companies have come here to visit our factory. Our company’s headquarters is near Beijing, China. It is located in Daechang Chaobaihe High-tech Industrial Zone of Petroleum Equipment in Hebei Province and has established branches in the United States and Russia. We are the sole manufacturer of vibrating mesh screens that passed the US API RP13C test until 2018. Our vibrating screens can be used in GN shakers and other mainstream brands of shakers at home and abroad.

GN solid control vibration screen product technical requirements:

1,Structure requirements: The screen within API60 adopts a 2-layer mesh structure, and the screen above API 60 adopts the 3-layer mesh structure.

2,Appearance requirements: no damage to the mesh surface, smooth surface, no broken wire, no wire drawing, no obvious color difference, clean, tidy, no obvious protrusion, no break, except for process requirements, no blocking hole, no leakage , Tightening is good, no effect of the use of fold phenomenon smooth border, no silk, no burr, no front edge, glue stick strong.

Note: The wavy network must be polished on both sides, the overall smooth, groove grinding, no leakage plug hole, no leakage on the back, the network surface pressure resistance, hand pressure without distortion, handle solid plastic.

3, welding requirements: no seam welding seam direction, no trachoma. There is no leakage in the direction of the transverse seam. Frame, no deformation of the board, no penetration, four corners need to be polished, the edges of the edges do not hurt the hand.

4, size requirements: size error range ± 0.5 ~ 1mm, mesh number is accurate, can meet the corresponding shaker installation and tension.

5,Packaging requirements 1: The carton is packed in a carton (the single screen can be packaged with plastic film). The two sides of the carton need to be affixed to the product label.

Note: When two screens are packaged in the same carton, they need to be placed adjacent to each other, with a soft material in between. A carton allows a maximum of 2 screens.

Comparison instructions:

1) ASTM refers to the American Materials and Testing Association, ASTM E11:01 mesh number is also ISO 3310-1:2000 mesh number, and the ASTM mesh number corresponds to the separation particle size refers to the single-layer screen mesh according to the ASTM standard wire diameter woven screen. Cloth size corresponding to the size of the separation. The mesh number corresponding to the screen usually refers to the mesh number of the screen mesh. However, the screen is usually composed of 2 or 3 layers. The mesh size corresponding to the mesh does not equal to the mesh size of the screen after compounding.

2) API refers to the American Petroleum Institute. The “Screen API Number” is a code according to API RP13C or ISO13501 standard. The separation particle size corresponds to the interval after the composite three-layer screen is separated to obtain the separation particle size. When ordering screens, we usually require customers to provide the required API code, or want to achieve a separate particle size, which can more accurately determine the ratio of the screen.