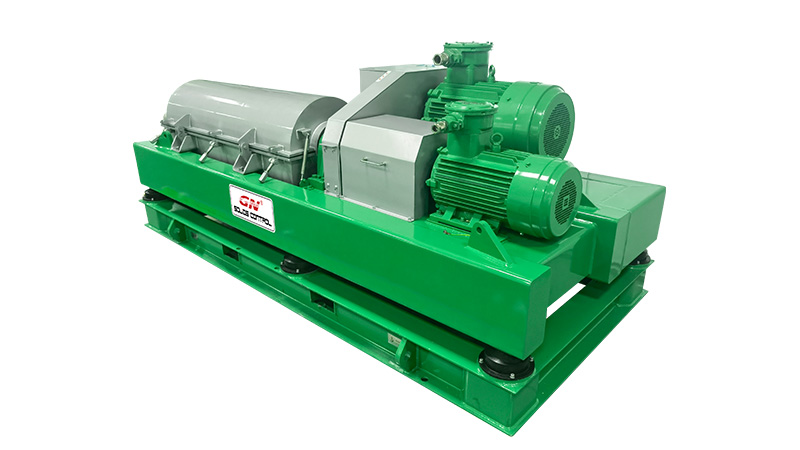

The GNLW363G is a 14-inch decanter centrifuge widely applied in the oil and gas drilling industry, known for its efficiency and versatility in handling drilling fluids. GN Solids Control provides this model with three different drive options to meet varied operational needs and budget requirements: a stable fixed-speed version, a fully hydraulic drive (FHD), and a variable frequency drive (VFD) for adjustable operation. This flexibility allows drilling operators to choose the most suitable configuration based on project demands, cost considerations, and site conditions.

One of the common challenges operators face is selecting the right centrifuge speed for their specific application. The speed of a centrifuge directly influences the separation efficiency, making it a critical factor in drilling mud treatment. To address this, GN Solids Control emphasizes the importance of understanding the role of centrifuges within a complete drilling mud system.

Typically, a full drilling mud system incorporates two centrifuges working in tandem, each serving a distinct function. The first is the low-speed centrifuge, which is primarily used to recover barite. In weighted drilling fluids, barite is added to increase mud density. By operating at a lower speed, this centrifuge selectively recovers barite particles from the mud, helping to maintain the required density while reducing mud weight and cutting down on material costs.

The second is the high-speed centrifuge, which becomes essential after the drilling system has been in circulation for a period of time. During extended operations, ultra-fine solids gradually accumulate in the drilling fluid. These particles are too fine to be removed by hydrocyclones. The high-speed centrifuge is specifically designed to remove these ultra-fine solids, preventing the mud weight from rising uncontrollably. The solids separated at this stage are discharged as waste, while the cleaned fluid is returned to the system for reuse.

By employing both low-speed and high-speed centrifuges, operators achieve optimal drilling fluid management. The GNLW363G, with its range of drive options and reliable design, provides a comprehensive solution for efficient solids control, improved mud quality, and cost-effective drilling operations.