NEWS

Pitless drilling water based mud waste treatment package unit for Sinopec Project

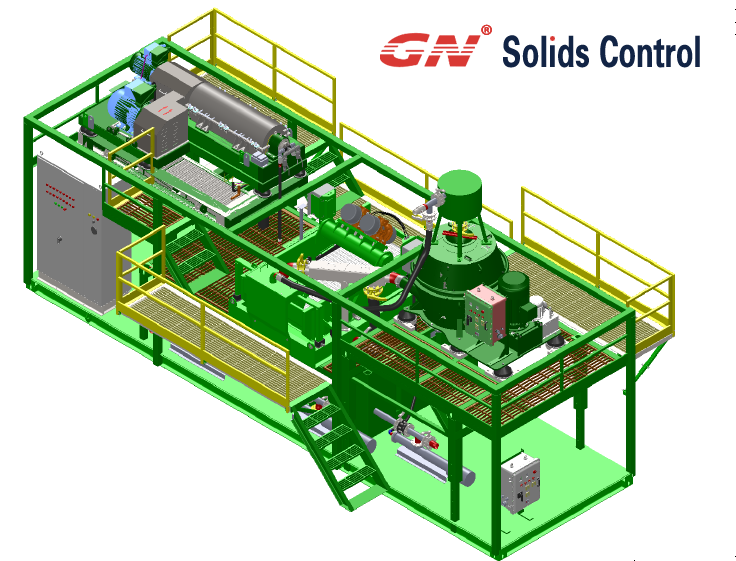

This is GN Solids Control 24th set pitless drilling WBM treatment equipment for Sinopec Project from middle of 2014.As we know, the new regulations for China oilfield environment has driven the demands for the pitless drilling. And the drilling company need to have no pit for the drilling, and no pollution discharge from the drilling. This gives good opportunities for GN Solids Control domestic market.

As a worldwide leading brand for drilling waste management, GN Solids Control has supplied products to over 60 countries and regions. With our extensive experience for the waste management, GN provide following series of products for the drilling waste treatment.

Vertical Cuttings Dryer

High G Drying Shaker

Drilling Waste Centrifuge

Dewatering Unit

Drilling Cuttings Solidification Unit

Screw Conveyors

Fluids or waste transfer pumps.

And more is coming soon which are in development.

About the Sinopec waste treatment projects:

For this project to Sinopec, it is a packaged WBM waste treatment system with Vertical Cuttings Dryer, High G drying shaker, and Variable speed centrifuge. The drilling waste transferred to vertical cuttings dryer or the High G drying shaker to take the drilling fluids from the waste cuttings, and the VFD decanter centrifuge will handle the fluids and return the clean drilling fluids to the active mud tanks.

For the fluids, the client may need to do dilution or dewatering to get the required density of mud for the continues drilling. The solids discharged from high G drying shaker or

vertical cuttings dryer will go to the solidification unit for treatment.

Case Study Videos: http://www.gnsolidscontrol.com/drilling-video/