For proper mixing and suspension of solids, the mud agitator must be properly sized and installed.

To properly size a mud agitator, proceed as follows:

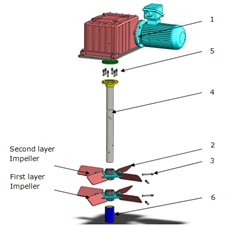

1. Select desired style – horizontal with welded or casting impeller

2. Determine available electric power – 440V/460V/380,60HZ , 380V/400V/415V,50HZ or customized.

3. Select horsepower and impeller(s) as determined by the following factors:

a. Tank design – round or square

b. Tank dimensions

c. Maximum mud weight

d. Desired turnover ratio (TOR)

After gathering the required information, the agitator can be properly sized to meet the horsepower demand and correct agitation for the application. GN Solids Control as world top 4 solids control and waste management supplier,can offer customized agitator size to meet different tank situation.

To ensure accurate sizing, GN recommends clients to communicate with GN people to make sure size and model.

Following are operational recommendations for mud agitators:

1. Maintain uniform tank dimensions, i.e. equal width-to-length ratio or as close as possible to equal.

2. Avoid TOR values greater than 85 seconds, as this may jeopardize solids suspension.

3. Avoid TOR values less than 40 seconds, as this may result in formation of a vortex and increase air entrapment.