Articles

GN Bored Pile Desander Plant Video

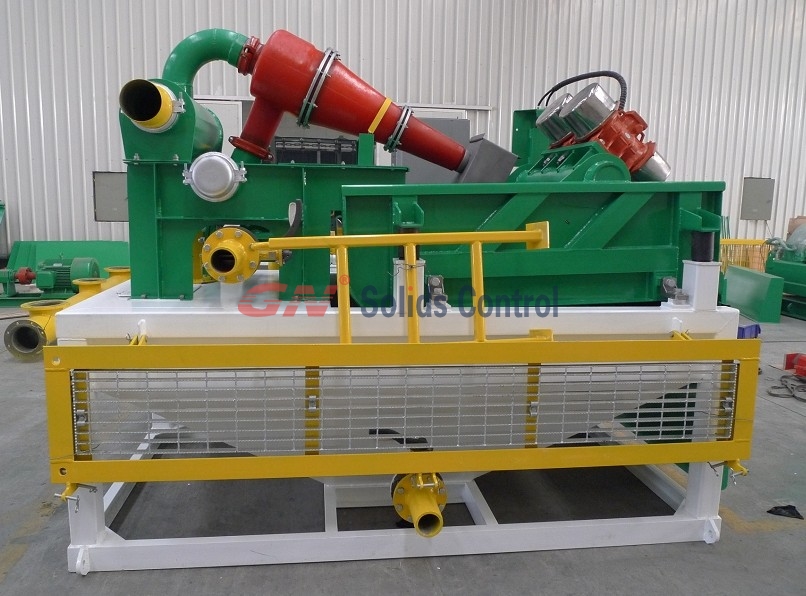

GN bored pile desander mud cleaning machine has been widely used in Asia countries to recycline drilling fluids for the foundation construction.

|

|

Bored piles are cast in place cylindrical piles excavated either by use of rotary equipment operated augers ,or buckets, under static drilling mud or large drill bit (for hard rock) with reverse circulation.The reason to use bored pile desander unit is that Bored piles installed in common soil with the presence of water table, generally require the use of a short temporary steel casing and a drilling fluid as static suspension to provide support to the surrounding soil while excavating the pile and until complete backfill of the pile excavation with concrete, in order to prevent cave-in of the excavation and destabilizing the surrounding soil formation.

GN Bored Pile Desander Jobsite Working Videos

Models of GN Bored Pile Desanding Plant

GNMS series Bored Pile Desanding Plant is simplified mud recycling system, After intermediate mud pit, GN mud recycling system can efficiently separte the solid and liquid, lower the solids content in recycling mud, drying the waste solids. The bored desander plant is very compact design for easier transportation, and more economic.GN Bored Pile desanding plant including following models:

GNMS-200D for handling 200GPM (50m³/h)

GNMS-500D for handling 500GPM (120m³/h)

GNMS-1000D for handling 1000GPM (240m³/h)

|

|

High Capacity is also available as per customer's requirements.

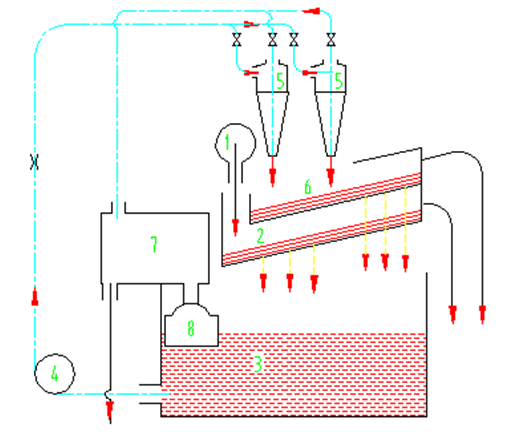

Flow Line of GN Bored Poile Desander

The sand pump sucked the mud from the Sediment Basins or mud compartment, then enter into bottom shaker(2) through inlet pipe(1), the particle size which is larger than 0.5mm will be separated out and flow to mud storage trough(3), the slurry pump (4)sucked from mud storage trough(3), the mud was jetted to hydrocyclone(5), the solids/sand was discharged to upper shaker(6) from the outlet nipple of the desander cone. After dewatering process of the upper shaker(6), the dry slag charge was separated out, the mud passed the upper shaker was back to mud storage trough(3),the clean mud entered into mud storage tank(7) through cone overflow pipe, then flow to mud outlet pipe.

There is a Backflush unit installed in the outlet of the slurry pump, connected with mud storage trough. It can agitate the deposition particles,in case of any silting-up in mud storage trough.

In the mud circulation process, there is a fluids level float between mud storage tank and mud storage trough , it can balance the fluids level . Once the out mud is more than supplied,the float will down with the fluids level, then mud will flow to mud storage trough from mud storage tank by the opening additional mud pipe, then the mud level will be up ;if the supplied mud is more than out, the trough will overflow